Quality Inspection for Flanged Full Bore Valve - wafer 150LBS metal seated triple offset Butterfly Valve with gear Operated MBV-00150-6W – Deye

Quality Inspection for Flanged Full Bore Valve - wafer 150LBS metal seated triple offset Butterfly Valve with gear Operated MBV-00150-6W – Deye Detail:

Quick Detail

Design standard: API609

Body material: CF8M

Nominal diameter: 8″.6” 12”

Pressure: CL150LBS

End connection: RF. Flange/FF flange ANSI B 16.9

Face to face: EN558 Series 13

Normal. Working temperature: -45℃~+650℃.

Test and inspection: API 598.

Bubble Tight Closure

Fire Safe Function

Blowout-Proof Stem

Renewable Seat Butterfly valves.

Product Range

Metal Seat Butterfly Valve API ANSI

Pressure Rating from 150LBS to 2500LBS.

Size Range: 2”-24”

Face to face: API 609 & BS5155 & ISO5752 & BS EN558 SERIES 20/14/16

Available Body Material : ASTM A216WCB/LCB/WCC/CF8/DUPLEX 4A 5A

Available Body Seat: overlay 13cr/STL /SS316

Available Dis Material c: ASTM A216WCB/LCB/Stainless steel /SDSS

Availed Protect Ring: A105/LF2/CF8M

Available Laminated Seal: SS316+SS316/Graphite /PTFE /Teflon

Optional available on request

Metal to Metal Seal: A182F316+Stellite STL

Performance:

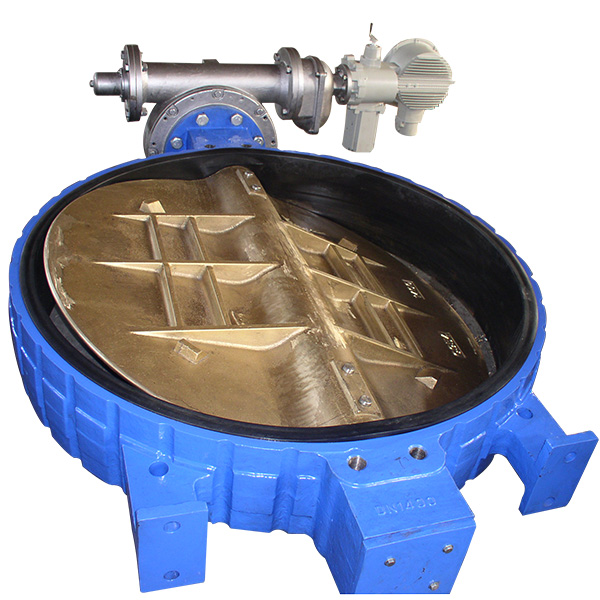

Three-offset butterfly valve, the structural feature is that the cone-shaped axis of the sealing surface of the butterfly plate is deviated from the cylindrical axis of the body while the eccentric shaft position of the double-eccentric stem is eccentric The sealing cross-section is no longer a true circle, but an ellipse, the shape of the sealing surface is therefore asymmetric, one side is inclined to the body centerline, and the other side is parallel to the body centerline. The biggest feature of this third eccentricity is that the sealing structure is fundamentally changed. It is no longer a position seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but depends entirely on the contact surface pressure of the valve seat to achieve the seal. The effect, therefore, solved the problem of zero leakage of the metal valve seat in one fell swoop, and because the contact surface pressure is proportional to the medium pressure, high pressure and high temperature resistance are also solved.

Application:

oil and gas mining, offshore platforms, petroleum refining, petrochemicals, inorganic chemicals, energy generation, and other important pipelines.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Quality Inspection for Flanged Full Bore Valve - wafer 150LBS metal seated triple offset Butterfly Valve with gear Operated MBV-00150-6W – Deye , The product will supply to all over the world, such as: Malta , Mexico , Madagascar , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.