Hot sale C95800 Plug Valve - triple offset lug 150LBS ANSI Butterfly Valve – Deye

Hot sale C95800 Plug Valve - triple offset lug 150LBS ANSI Butterfly Valve – Deye Detail:

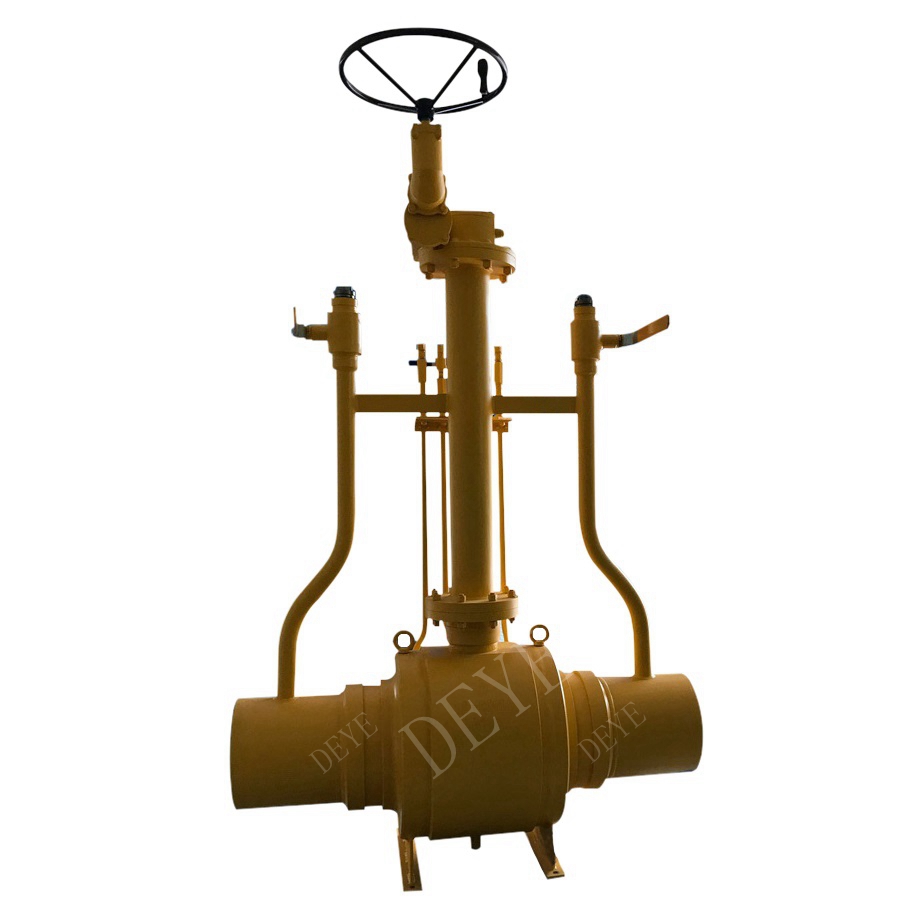

triple offset lug 150LBS ANSI Butterfly Valve

Design standard: API609

Body material: stainless steel

Nominal diameter: 16” DN400

Pressure: 150LBS

End connection: BW ANSI B16.25

Face to face: EN558 Series 20

Normal. Working temperature: -45℃~+650℃.

Test and inspection: API 598.

Fire Safe Function

Blowout-Proof Stem

Product Range

Triple offset Butterfly Valve API ANSI

Pressure Rating from 150LBS to 1500LBS PN10-PN2500

Size Range: 2”-24” DN50-DN600

Design Code: API609 & customized

Face to face: EN558-20

Available Body: WCB/CF3M/CF8/CF8M/SDSS/DSS

Available Integral Body Seat: overlay 13cr/Stellite STL /SS316

Available Protect Ring: A105 /SS304/SS316

Available Laminated Seal: SS316+Graphite/ SS304+Graphite

Optional available on request

Renewable Seat 17-4H/SS304/SS316

Soft Seal: PTFE, TELFON, NBR

Performance:

1. The wafer butterfly valve adopts a three-eccentric sealing structure, the valve seat and the butterfly plate have almost no wear, and have a tighter sealing function

2. The sealing ring is made of stainless steel, which has the dual advantages of metal hard seal and elastic seal. It has excellent sealing performance under low and high temperature conditions, has the characteristics of corrosion resistance and long service life

3. The sealing surface of the butterfly plate adopts surfacing cobalt-based hard alloy, and the sealing surface is wear-resistant and has a long service life.

4. Large size butterfly board adopts quilt frame structure, high strength, large flow area, small flow resistance

5. The wafer-type hard-sealed butterfly valve has a two-way sealing function. It is not restricted by the flow direction of the medium during installation, nor is it affected by the position of the space. It can be installed in any direction

6. The driving device can be installed in multiple stations (rotation 90 ° or 180 °), which is convenient for users to use

Application:

widely used in the water conservancy projects, tap water, power circulating water, petroleum, chemical industry and other industrial pipeline

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Hot sale C95800 Plug Valve - triple offset lug 150LBS ANSI Butterfly Valve – Deye , The product will supply to all over the world, such as: Guatemala , Sao Paulo , South Korea , We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!