Good quality Api Pressure Seal Valve - High pressure WCB 2500LBS strainer/Filter with welded End YC-002500-2.5 – Deye

Good quality Api Pressure Seal Valve - High pressure WCB 2500LBS strainer/Filter with welded End YC-002500-2.5 – Deye Detail:

Quick Detail

Design standard: API 600.ANSI B16.34

Body material: WCB. Carbon Steel

Filter: SS304

Mesh No. 40, 80. 160.

Nominal diameter: 2” 2.5” 3”

Pressure: CL2500LBS

End connection: BUTT WELDED SCH160

Face to face: ASME B16.10.

Working temperature: -29℃~+425℃.

Drain Plug Design.

Test and inspection: API 598.

Ps strainer

On Request

Available Material: Carbon steel, Stainless steel, Alloy steel. A216WCB/LCB/WC9/C5/CF8M/CF3

Optional Screen filter/Mesh: SS316, SS316L, customized

Optional End connection: FLG RF RTJ, BW, SW,TH

ANSI B16.5, ANSI B16.25, ANSI B16.11, ANSI B 1.20.1

Range of rating: 150lbs~2500lbs (PN16~PN420).

Range of diameter: 1/2″~24″ (DN15~DN600).

Performance and functions:

“Filter” is a device on the conveying medium pipeline, usually installed at the inlet end of the pressure reducing valve, pressure relief valve, fixed water level valve or other equipment, used to intercept impurities in the medium to protect the valve and equipment.

Maintenance:

- The main part of the filter is the filter core. The filter core is composed of the filter frame and stainless steel wire mesh. The stainless steel wire mesh is a wearable part and needs protection;

- When the filter works after a period of time, certain impurities have settled in the filter core. At this time, the pressure drop increases and the flow rate will decrease. It is necessary to remove the impurities in the filter core in time;

- When cleaning the impurities, pay attention to the stainless steel wire mesh on the filter core cannot be deformed Or damage, otherwise, the installed filter, the purity of the filtered media does not meet the design requirements, compressors, pumps, instruments and other equipment will be destroyed;

- If the stainless steel wire mesh is deformed or damaged, it needs to be replaced.

Application:

Y-type filter is suitable for water, oil and gas

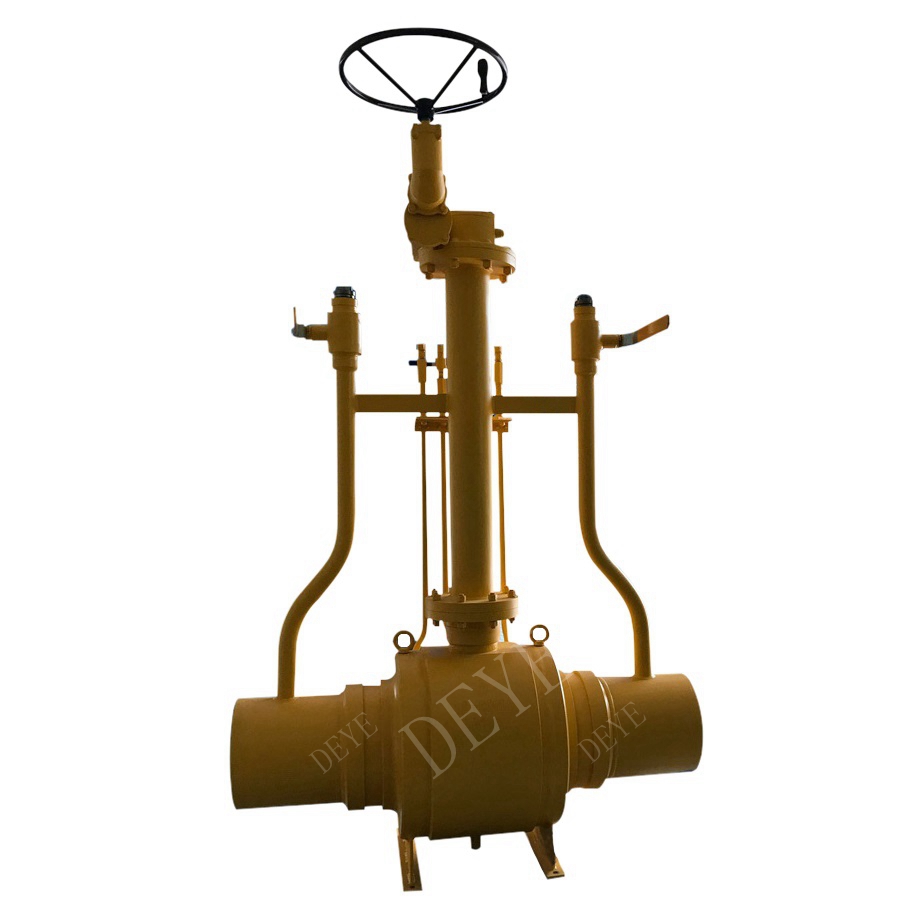

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high-quality handle, reasonable rate, superior services and close co-operation with prospects, we are devoted to furnishing the best price for our customers for Good quality Api Pressure Seal Valve - High pressure WCB 2500LBS strainer/Filter with welded End YC-002500-2.5 – Deye , The product will supply to all over the world, such as: Berlin , Orlando , El Salvador , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.