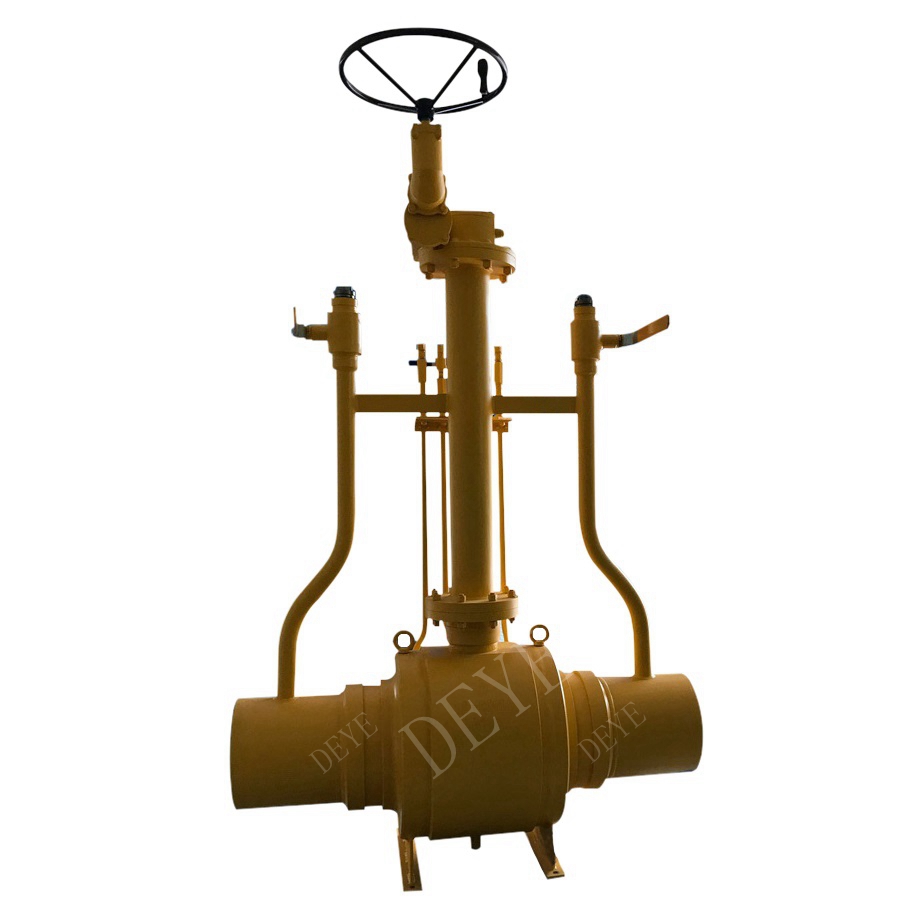

Factory supplied Flanged 600lbs Butterfly Valve - A105 forged 800LBS 3-pcs ball valve with NPT (BV-800-3-4N) – Deye

Factory supplied Flanged 600lbs Butterfly Valve - A105 forged 800LBS 3-pcs ball valve with NPT (BV-800-3-4N) – Deye Detail:

Quick Detail:

Design standard: ASME B16.34/API600

Body material: A105 ball valve

Nominal diameter:3/4″.

Pressure: 800LBS

End connection: NPT

Face to face: ASME B16.10.

Mode of operation: lever Operated

Test and inspection: API 598.

Reliable sealing performance and small torque;

Graphite packing;

Anti-blowout stem design & Fire Safe;

Product Range:

Available Material: CF8M, CF8, CF3M, WCB

Pressure Rating: 1000PSI (PN63), 2000SI

Optional Construction: 3pcs, 1pcs, 2pcs body.

Full Bore/ Reducing Bore

Optional Ends: BW, flanged RF FF, NPT B16.20.1 , BSP DIN2999. SW

Optional seal: PTFE, RPTEF, Nylon, Peek, Metal Seated

Size Range: 1/2”-4” DN15-DN-100mm

Optional locking device

Optional ISO 5211 top flange.

Performance:

1. Pre-loaded with leaf spring is adopted during the design, the sealing force is designed reasonably, the opening and closing are flexible, and the sealing is reliable.

2. suitable for structures containing solid particles, slurry and other media or structures with higher temperature resistance.

3. Adopted bottom-mounted valve welding, and provided an inverted sealing structure is to ensure reliable sealing of the material.

4. Suitable for urban construction, chemical industry, metallurgy, petroleum, pharmaceutical, food, beverage, environmental protection

Application:

Applicable temperature: -196 ~ 350 ℃, used to cut off or connect the medium in the pipeline, choose different materials, can be used to transport water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea, etc., widely Used in petroleum refining, long-distance pipeline, chemical industry, papermaking, pharmaceutical, water conservancy, electric power, municipal administration, steel and other fields.

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Factory supplied Flanged 600lbs Butterfly Valve - A105 forged 800LBS 3-pcs ball valve with NPT (BV-800-3-4N) – Deye , The product will supply to all over the world, such as: Dubai , Israel , Naples , We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.