Short Description:

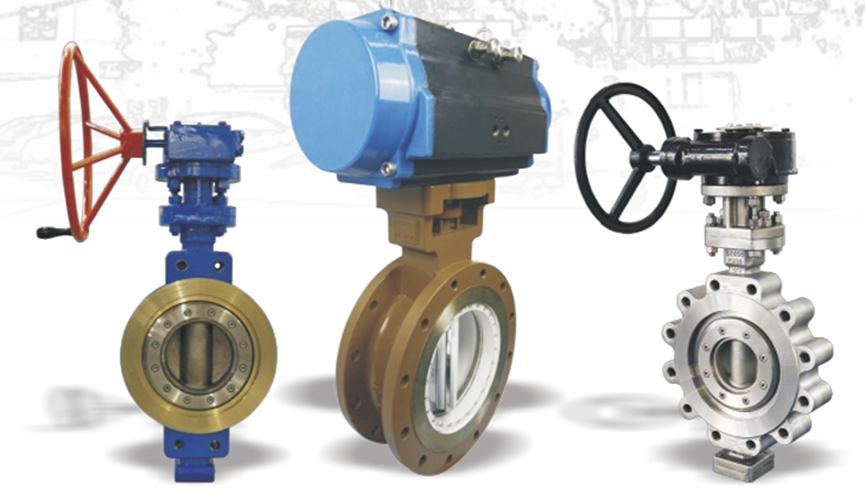

Deye Triple Offset Butterfly Valves are designed for demanding applications.

Unique seat and body construction allows for easy configurability and maintenance, without

compromising shut off capability or service life.

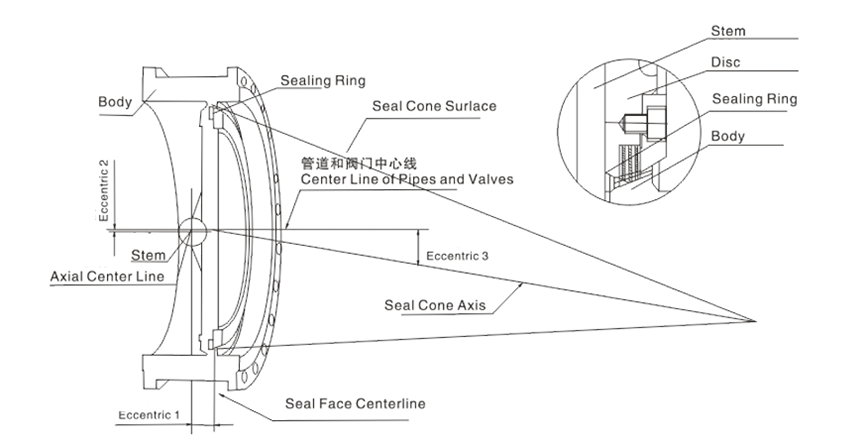

Triple offset Design of the Butterfly valves

Design Specifications

Valve Design & Pressure Temperature Rating: API609&ASME B16.34

Fire Tested: API 6FA/API 607

Actuator Mounting: lSO 521 1

Face to Face: API 609,ASME B16.10,IS0 5752

Seat Testing: APl 598,1S0 5258

Flange Drilling: ASME B16.5, ASME B16.47

Valve Marking: MSS-SP-25,ASME B16.34

Fugitive Emissions: lS0 15848 Standard

Features:

• High Temperature Resistance

• High Corrosion Resistance

• Fire Safe Design

• Metal to Metal seal

Optional: Laminated Seal

1) Metal /Graphite/ Metal

2) SS316/PTFE/SS316

• Field-Replaceable Seat & Seal

• Low torque

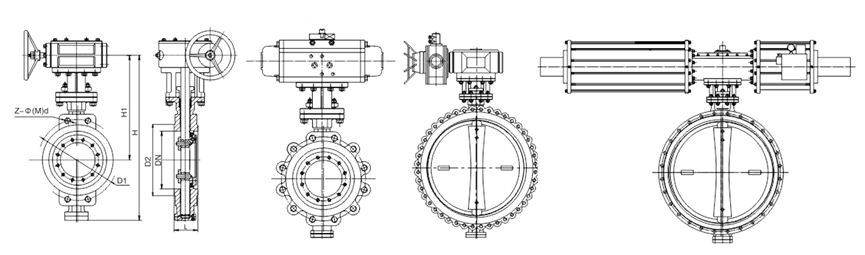

Triple offset Butterfly Valves are suitable for gearbox+ handwheel

Triple eccentric Valves are suitable for Pneumatic actuators

Three eccentric Valves are suitable for electric motor Actuators

Valves Connection: Wafer, Lug, Flanged type

Main Technology Parameter

| NominalPressure |

Test Pressure (MPa) at room Temperature |

Applicable Temperature |

Medium |

| Shell Test |

High Pressure Seal |

Low pressure Seal |

| Class 150 |

2.93 |

2.07 |

0.6 |

-29~425℃ |

Water.Steam,Oil,Seawater |

| Class 300 |

7.58 |

5.52 |

0.6 |

| Class 600 |

15 |

11.03 |

0.6 |

| Class 900 |

24 |

17.6 |

0.6 |

Material for Main Parts

| Parts Name |

Material |

| Body |

WCB、WC6,、CF8, CF8M,CF3M, DUPLEX SS 4A 5A 6A UNS31803 UNS32750 |

| Disc |

WCB、WC6,、13CR, CF8, CF8M,CF3M, DUPLEX SS 4A 5A 6A UNS31803 UNS32750 |

| Stem |

17-PH, 2CR13, SS316, SS304, F51, F53, F55 |

| Body Seal |

Metal 13cr, SS304, SS316, STL, F51, F53, F55 |

| Disc Seal |

Metal to Metal, Laminated Metal /Graphite, Metal/PTFE |

| Packing |

Flexible Graphite, PTFE |

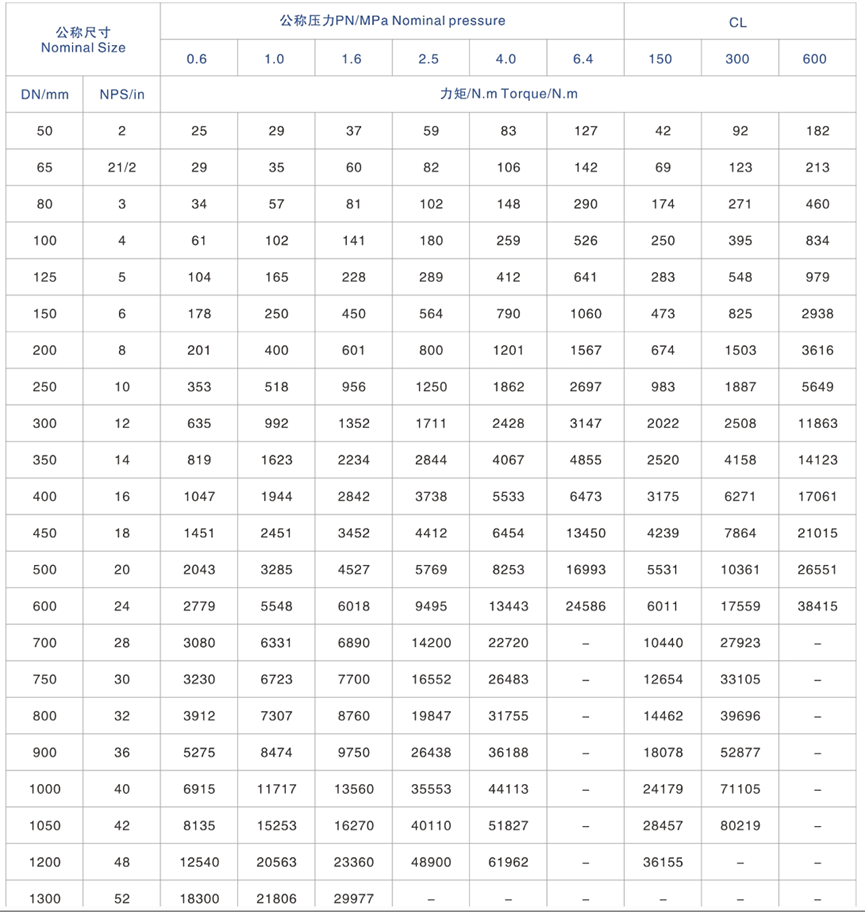

Torque Value (N.M) for triple offset Butterfly valve

The Possible Fault and Breakdown

| The Fault |

Reason |

Solution |

| Valve Seal Leakage |

1.There are debris on the disc and seal ring.2.The closing position of disc and seal ring is not correct.

3.counter flanges are compressed unevenly and un-tightly

4.Direction of testing pressure isn’t according to the arrow requirements |

1.Clean the valve cavity and eliminate the debris.2.Adjust the screws of worm gear and electric actuator or other driving devices to correct the valve closing position.

3.Fitting flange at external position should be compressed evenly and tightly.

4.Direction of testing pressure should depend on the flow arrow direction |

| Valve Leakage on both Sides |

1.Sealing gaskets of both ends are invalid2.Pipe flange is compressed unevenly and un-tightly

3.Gaskets on the up and bottom of seal ring are invalid. |

1.Replacing sealing gaskets2.Compressing flange bolts (uniform force )

3.Removing the plate ring of valve and replacing the invalid gasket |